Press/Media: Newspaper Article

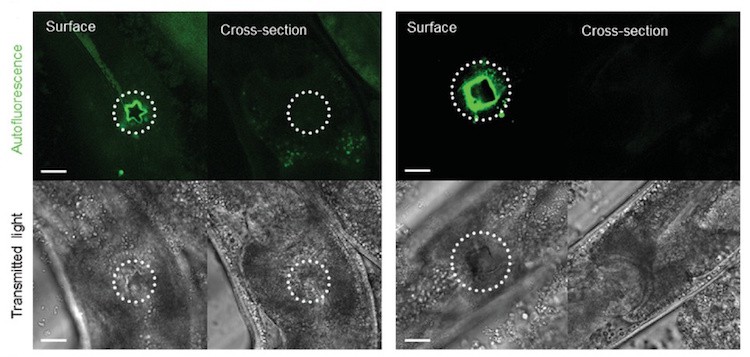

3D printing in a living organism: star (left) and square (right) shapes printed onto an anesthetized C. elegans worm’s head, imaged by confocal fluorescence and transmitted light at x40, without damaging the worm. Scale bar, 10 µm. (Courtesy: CC BY 4.0/Adv. Mater. Technol. 10.1002/admt.202201274)

3D printing in a living organism: star (left) and square (right) shapes printed onto an anesthetized C. elegans worm’s head, imaged by confocal fluorescence and transmitted light at x40, without damaging the worm. Scale bar, 10 µm. (Courtesy: CC BY 4.0/Adv. Mater. Technol. 10.1002/admt.202201274)

Researchers at Lancaster University have succeeded in directly printing three-dimensional conducting polymer structures inside a living organism. While the process is in its very early stages, if properly developed, it could be used to print next-generation implants for a variety of medical applications, including real-time health monitoring and interventions such as neuromodulation. Human–computer interfaces might also be a possibility.

The researchers, co-led by materials chemist John Hardy, used a high-resolution fast pulsed laser 3D printer to generate volume pixels (voxels) in which two photons of light with a wavelength of roughly 780 nm excite a molecule (in this case the photoinitiator Irgacure 2959) from one energy state to a higher energy state in a single quantum event. This in turn initiates polymerization of the constituent monomers in the printer “ink”. The polymerized product, polypyrrole, is electrically conductive and can thus be used to build electronic circuits.

“We started with proof-of-concept studies to print an electrical circuit within an elastomer (polydimethylsiloxane, PDMS) matrix and used the electrical contact points printed on top of the PDMS to stimulate neurones in a slice of mouse brain tissue that were kept alive in vitro, evoking neuronal responses that were similar to those seen in vivo by our colleague Damian Cummings at University College London,” explains Hardy.

The researchers adapted this additive manufacturing process to work directly in nematode worms (C. elegans). “While printing in live worms sounds simple in theory, it was not a given,” explains co-team leader Alexandre Benedetto. “We needed to make sure that the precursor monomer mixture was biocompatible, which is more difficult than once the material is polymerized and ‘inert’, and that the light used to polymerize the monomer does not harm the animals by burning surrounding tissue. This was possible because we used lower energy lasers and a ‘two-photon’ set up.”

The researchers also had to immobilize the worms during the 3D printing procedure to stop them from wiggling, he adds. “To do this, we anaesthetized them and trapped them between two glass coverslips containing micro-channels made of transparent silicon. These grooves were moulded on a piece of old vinyl record disc.

The roundworms ingested some of the ink and, because they are transparent, it was possible to focus the laser beam within them. Their transparency also makes them more vulnerable to heat, light and desiccation than human skin – so printing on these animals therefore represents a significant step towards de-risking the technology.

The researchers, who report their work in Advanced Materials Technologies, hope to print more complex circuits in the future using their technique. They are now looking into the scope of the structures that they can print inside and on live biological tissue. The ethical implications of the research also need to be addressed. They say they will be doing this part of their project with colleague John Appleby.

“If we think about applying this type of approach to human health, the 3D printing setup needs to be modified since we will not be dealing with microscopic or very thin objects,” Benedetto tells Physics World. “One way to do this is to miniaturize the 3D printing equipment so that it can be hand- or robotic-arm-held.”

| Title | Laser-printed electronics could create next-generation medical implants |

|---|---|

| Degree of recognition | International |

| Media name/outlet | Plato AI |

| Primary Media type | Web |

| Country/Territory | United States |

| Date | 19/04/23 |

| Description | Researchers at Lancaster University have succeeded in directly printing three-dimensional conducting polymer structures inside a living organism. While the process is in its very early stages, if properly developed, it could be used to print next-generation implants for a variety of medical applications, including real-time health monitoring and interventions such as neuromodulation. Human–computer interfaces might also be a possibility. |

| Persons | John Hardy, Damian M. Cummings, Alexandre Benedetto, John Appleby |